In today’s water and wastewater industry, choosing the right Construction Engineering and Inspection (CEI) firm is crucial for ensuring safe, reliable, and sustainable water and wastewater service to communities. Whether you’re embarking on a large-diameter linear pipeline project or a treatment plant facility expansion project, selecting the most suitable CEI firm can significantly impact the success and longevity of your project. In this guide, we’ll walk you through the essential steps to consider when choosing a CEI firm for your water or wastewater infrastructure project.

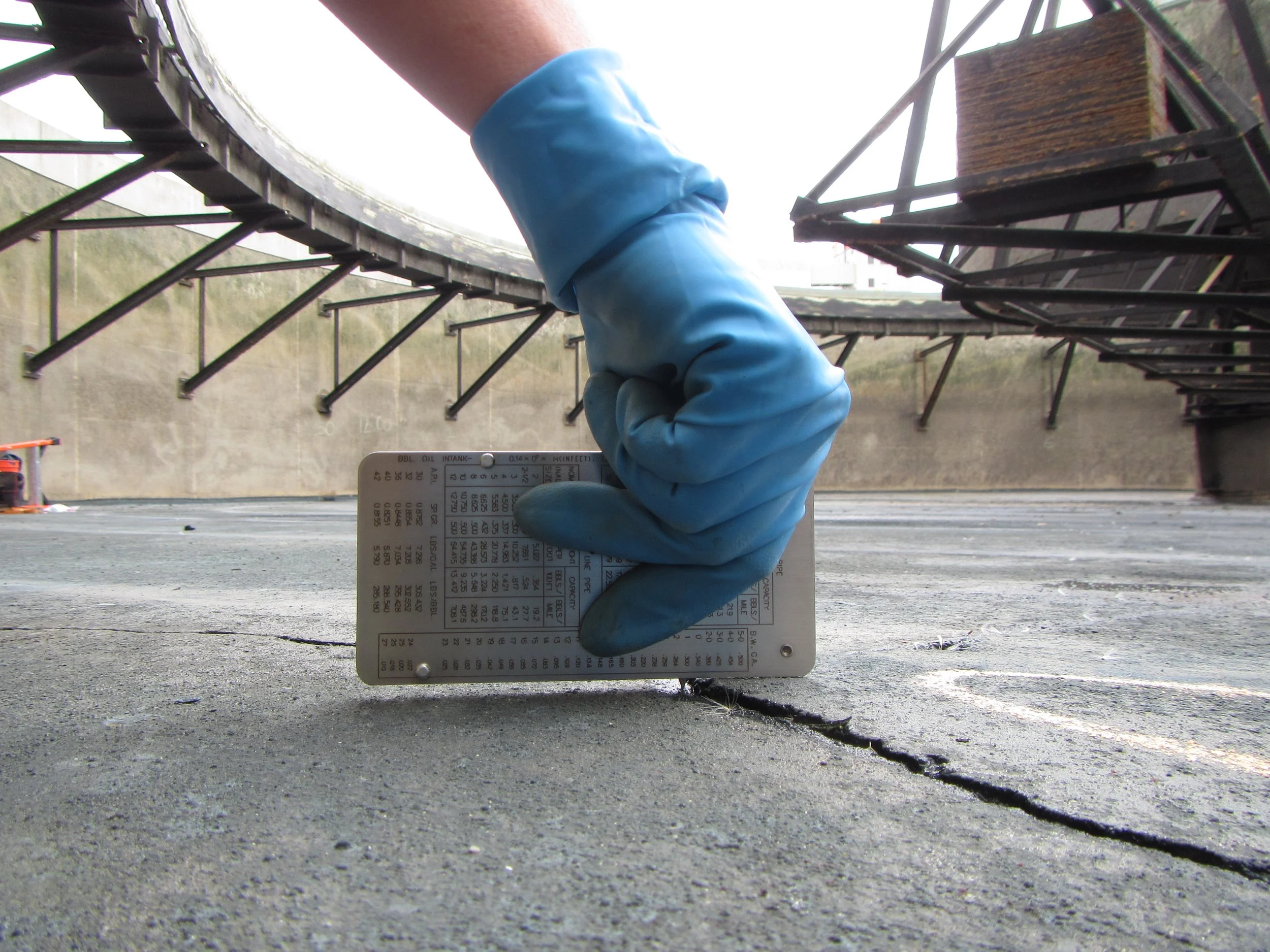

Surface Preparation: Key to Protective Coating Excellence

The old adage “preparation is key” couldn’t ring truer when applied to protective coatings in the corrosion prevention, water, and wastewater industries. Whether safeguarding a water storage tank against the elements or enhancing the lifespan of wastewater treatment process equipment, applying protective coatings is only as effective as the surface preparation performed before it is applied. V&A’s new blog post discusses the significance of surface preparation and provides an overview of industry standards. Protective coatings offer the first line of defense against the harmful effects of a corrosive environment on infrastructure.

Pipeline Electrical Continuity: An In-Depth Guide to Evaluation Techniques

Embarking on a journey to ensure the longevity and reliability of buried pipelines involves critically examining their electrical continuity. Understanding a pipeline's electrical continuity is paramount, especially when considering implementing cathodic protection systems to safeguard against corrosion. In this blog article, we dive into the complexities of determining electrical continuity by exploring corrosion experts' methods to test for continuity along existing pipeline alignments.

The Science Behind Foul Odor Emissions in Sewer Collection Systems

V&A’s newest blog article dives into the scientific details surrounding foul odor emissions in sewer collection systems. While the topic may not be the most glamorous, understanding the science behind foul odor generation and its release is crucial for developing and implementing odor control solutions. This informative article sheds light on ventilation dynamics that influence the dispersion and intensity of foul odors, explaining how airflow patterns and environmental conditions within sewer pipes contribute to the release of malodorous compounds.

Time-Tested Tactics for Infrastructure Condition Assessment

In the ever-evolving landscape of water and wastewater infrastructure management, the reliance on time-tested tactics remains paramount. As we navigate the complexities of maintaining and operating our built infrastructure assets, combining qualitative and quantitative data collection methods emerges as a steadfast approach to understanding and evaluating infrastructure condition. This blog article delves into the foundational principles that have stood the test of time, exploring the blend of qualitative insights and quantitative precision in condition assessment. Join us on a journey through the tried and true methods that have proven instrumental in ensuring the longevity, safety, and efficiency of our critical water and wastewater infrastructure assets.

The Significance of Study Duration in Sewer Flow Monitoring Programs

V&A’s latest blog article unravels the critical role of study duration in sewer flow monitoring programs. From hydraulic modeling and RDII analysis to compliance monitoring, we explore why the clock matters in understanding the operation of sewer systems. In wastewater infrastructure management, sewer flow monitoring programs are a critical tool for assessing the functionality and efficiency of sewer systems. A key parameter influencing the precision and reliability of these programs is the duration over which monitoring takes place.

This article explains why study duration is pivotal in extracting meaningful insights. From the nuanced calibration requirements of hydraulic models to the meticulous analysis of Rainfall-Dependent Infiltration and Inflow (RDII), the time-based scope of monitoring programs is a decisive factor in informing data-driven decision-making for sustainable sewer system operation.

Protective Coatings on Welded Steel Storage Tanks: Is It Time to Repair or Replace?

The decision to repair or replace a protective coating on welded steel storage tanks depends on several factors, including the condition of the existing coating, the extent of damage or deterioration, the remaining service life of the storage tank, budget considerations, and environmental considerations.

Generally, a high-quality protective coating on a well-maintained welded steel storage tank can sometimes have a lifespan of 20 to 40 years or even longer. However, premature coating failure can occur due to various factors, and ongoing inspections and maintenance are crucial to ensuring the longevity of the coating.

How does an owner know when to repair or replace protective coatings?

Unsung Heroes: Understanding the Crucial Role of Construction Engineering and Inspection

In the world of public works construction, where intricate bridges, robust roadways, and large-scale water/wastewater infrastructure shape our landscape, a group of professionals work diligently behind the scenes – Construction Engineering and Inspection (CEI) experts. Often, unsung heroes, these professionals play a pivotal role in ensuring that quality construction projects are delivered safely and in compliance with industry standards.

In our most recent blog post, we share the importance of CEI in the public works construction industry. From overseeing the intricacies of materials and testing to coordinating with various stakeholders, CEI professionals are the guardians of construction excellence. Join us as we delve into their responsibilities, the challenges they face, and their impact on the success of construction projects.

Factors Impacting the Cost of Pipeline Condition Assessment

Water and wastewater utilities face the challenge of maintaining infrastructure that has served for decades. Buried pipeline infrastructure poses accessibility challenges from physical limitations and operational constraints. Consequently, utilities must strategize effectively to plan for potential rehabilitation or replacement initiatives. The optimal approach involves conducting a comprehensive field-based condition assessment, ensuring the availability of up-to-date and precise data for informed decision-making. However, the logistics of gathering condition data can be challenging, impacting the pipeline condition assessment cost.

Cell-to-Cell Surveys for Identifying Active Corrosion on Mortar-Coated Steel Pipes

Corrosion in infrastructure systems, such as steel pipes, significantly threatens their structural integrity and longevity. Detecting and monitoring corrosion promptly is crucial to ensure the safe operation of these infrastructure assets. In the case of mortar-coated steel pipes, corrosion can occur underneath the protective mortar layer, making it challenging to identify without invasive investigative techniques. Cell-to-cell surveys assess the likelihood of active corrosion on mortar-coated pipe materials due to the loss of intimate contact between the steel cylinder and the mortar coating.

Confined Space Entry Cost for Condition Assessment of Municipal Infrastructure Can Be Influenced by Various Factors

Mitigating Wastewater Odors: What are my Options?

Wastewater odor issues are typically the result of hydrogen sulfide (rotten egg odor), H2S, produced within the wastewater during conveyance or treatment. H2S can wreak havoc in wastewater treatment systems as it leads to infrastructure corrosion, worker safety issues, and public odor complaints. To address these issues in public wastewater systems, owners and operators need to identify the source of the H2S and other odorous compounds and implement appropriate odor control measures. A comprehensive odor control strategy begins with an odor investigation to characterize the odor and identify the source. Once the odor sources are identified and clear treatment objectives are established, odor control strategies can be designed and implemented.

GACP vs. ICCP - Which Cathodic Protection System is Right for my Project?

Corrosion is a primary concern for pipelines as it can cause significant damage to the pipeline structure and potentially lead to leaks, which can be costly to repair and environmentally harmful. Cathodic protection (CP) systems help minimize the risk of pipeline leaks and damage by providing protection from potential corrosion issues. Often, the first decision the design engineer, owner, and operator of a pipeline needs to make after determining whether the soil is corrosive is whether to use a Galvanic Anode Cathodic Protection (GACP) or an Impressed Current Cathodic Protection (ICCP) system.

How do you know which cathodic protection system is suitable for your project?

Metallic Corrosion: Methods for Assessing Structure Condition

Metallic surfaces and structures commonly found in the water and wastewater industry include pipelines, gates, treatment plant basins, reinforcing steel embedded in concrete structures, access lids, and steel tanks. Metallic assets are critical components of water and wastewater systems; however, these assets are susceptible to corrosion which can be detrimental to system operations.

Engineers employ various methods to prevent electrochemical reactions from causing corrosion damage to metallic surfaces. Regular intervals of condition assessment are critical to evaluating metallic structure assets to identify and counteract corrosion before it becomes a costly and devastating problem.

Protecting Infrastructure – What’s the Difference Between Coatings and Linings?

Protective coatings and linings are regularly discussed in the corrosion, water, and wastewater industries. Often, coatings and linings offer the first line of defense against a corrosive environment's harmful effects on infrastructure. The term coatings is generally used for protective materials on a valve, pipe, tank, or sheet pile exterior. The term lining is usually used to describe the protective materials on the interior surfaces of a valve, pipe, tank, or concrete structure.

Condition Assessment Methods for Reinforced Concrete Structures at Wastewater Treatment Plants

As wastewater treatment facilities age, it is critical that the concrete structures are assessed at regular intervals to identify and locate areas of degradation early, while a repair is still a cost-effective solution. To many in the wastewater industry, Condition Assessment is defined as the engineering analysis of structures and facilities to determine the remaining service life. Condition Assessment includes the use of appropriate and established tools and techniques to measure the current condition of a structure or facility against industry standards. For V&A’s engineers, Condition Assessment is performed by collecting quantitative data in the field to complement visual investigations.

What's That Smell? Investigating Wastewater Odors

A comprehensive odor control strategy begins with an odor investigation to characterize the odor and identify the source. This article provides a high-level overview of a typical odor investigation approach.

Investigating offensive wastewater odors ensures that you are being a good neighbor, providing a safe work environment, and protecting critical infrastructure from corrosion caused by hydrogen sulfide. The sooner odor issues are addressed, the more cost-effective and impactful the solutions can be.

Mechanisms of Corrosion in Reinforced Concrete Structures at Wastewater Treatment Plants (WWTP)

Reinforced concrete is one of the most common construction materials, especially in the wastewater industry. Concrete, in its most basic form, is a mixture of water, aggregates, cement and reinforcing steel. Concrete is strong in compression and very weak in tension which is the reason reinforcing steel is added to form a composite structure.

While concrete used in wastewater applications can be quite resilient, proper design and corrosion protection are necessary to ensure the structure lasts through its intended service life.

Measuring Coffee and Corrosion: What is the “best” cup of coffee, and what is “bad” corrosion?

Sewer system defects and smoke testing for defect detection

Stormwater can enter sewer systems through a variety of inflow and infiltration (I/I) sources. Flow monitoring, system defect detection, and repair provide cost savings. Sources of inflow and infiltration can be difficult to locate. Smoke testing is a fairly simple and handy tool for quickly identifying system defects.