Chocolate chip cookies. Fresh cut grass. The ocean breeze. Each of these scents likely invokes a specific feeling or memory. Neuroscience tells us that the sense of smell is strongly linked to memory and emotion, probably more than any of our other senses. Our perception of odors as good or bad depends as much, if not more, on how we feel about past events associated with the memories these odors trigger as it does on what it actually smells like.

Odor complaints can often be one of the most perplexing problems when operating a wastewater system, due to their subjective nature and seemingly unpredictable pattern. A positive experience in how the odor complaints are handled will leave a lasting impression on stakeholders and operators alike. Having a well-structured procedure for documenting and investigating odor complaints is necessary to effectively manage these issues.

There are a number of considerations that may influence the scope and size of an odor control strategy, including regulatory requirements, corrosion concerns, and the desire to be a good neighbor. Clearly defining the goals of an odor control program is key to developing the most straightforward approach to mitigating odor emissions. Seemingly unrelated odor and corrosion issues are often influenced by a few key contributors that result in systemwide problems. Identifying the most effective odor control strategy requires a prioritized approach to eliminating the low hanging fruit and mitigating odor emissions across the entire system.

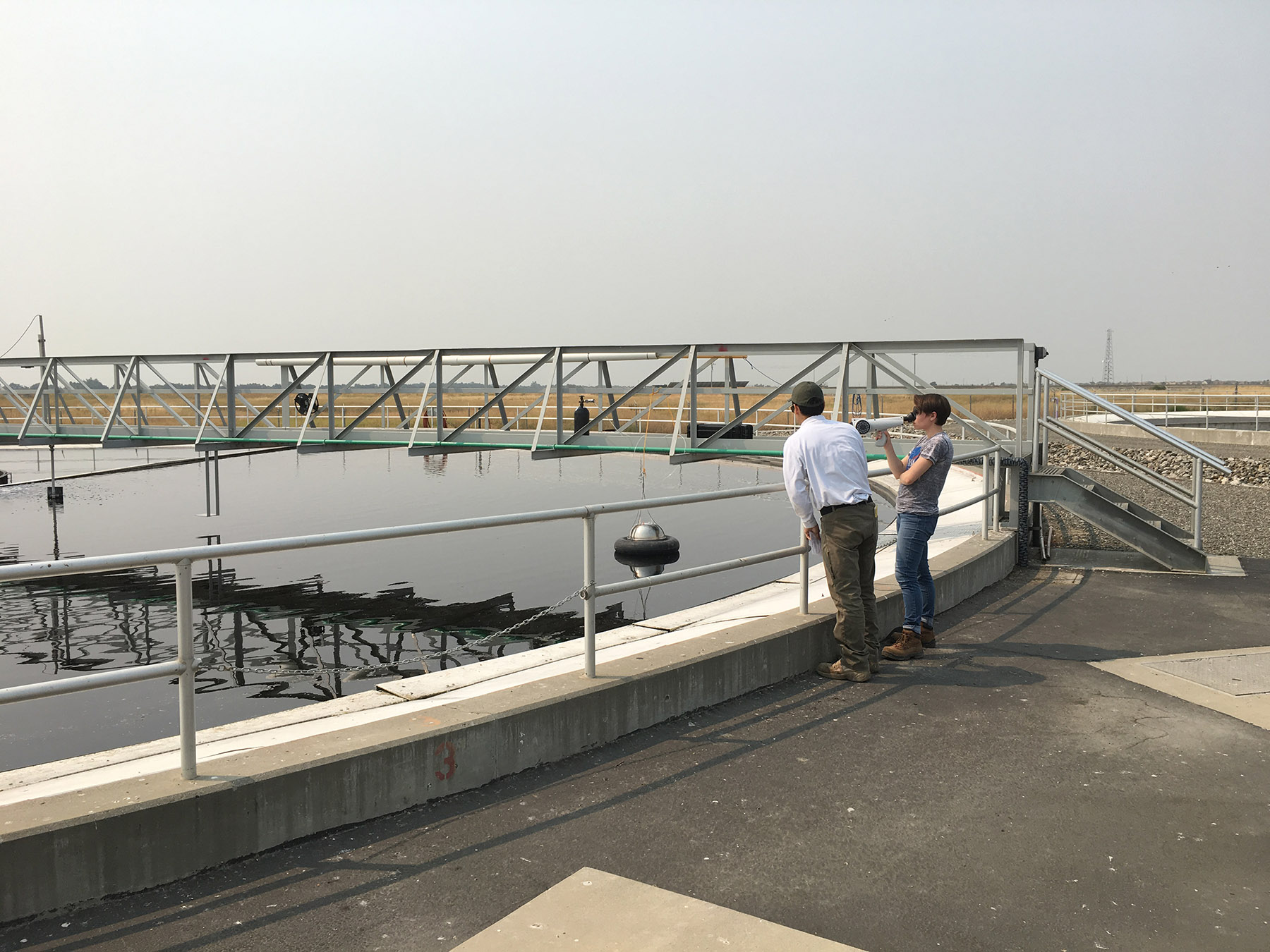

V&A uses a variety of tools to identify and characterize odor issues, including hydrogen sulfide and differential pressure monitoring, odor sampling, and ventilation and air dispersion modeling. Hydrogen sulfide is one of the most common parameters evaluated as it a good indicator of the source of both odor and corrosion issues. It is easily monitored, influences the technology selection and operating costs of most odor control solutions, and its generation rate can be incorporated into hydraulic models to compare alternative solutions and determine the impact of future infrastructure changes on the systemwide odor conditions.

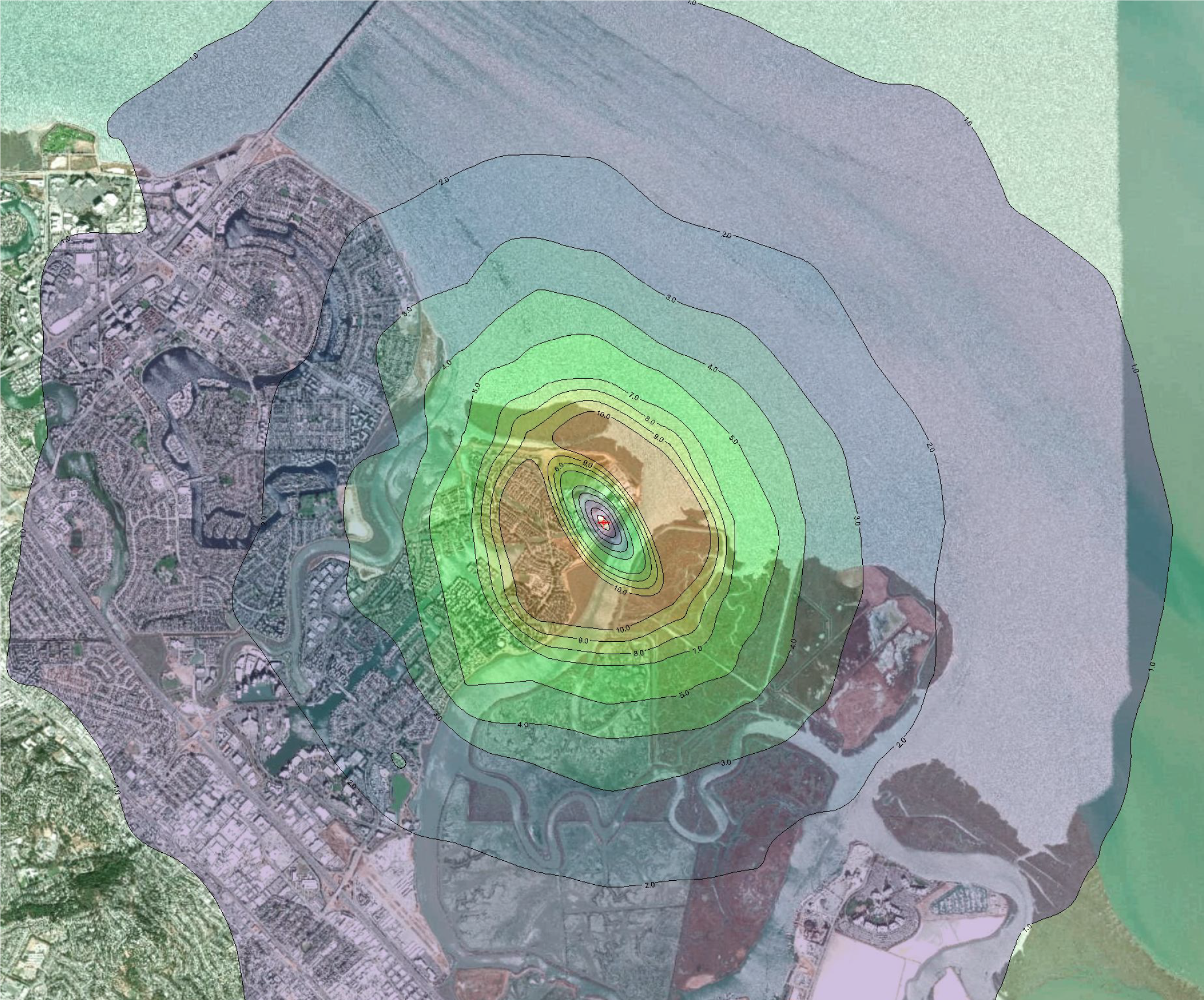

Quantifying odor complaints beyond subjective terms such as “terrible” or “unbearable” is important to monitor the effectiveness of the odor control strategy. Olfactometry measurements provide a repeatable and quantifiable basis for investigating odor complaints and comparing the relative “strength” of different odor sources. Once the odor concentration is known for a given odor source, V&A uses air dispersion modeling to determine the likelihood that odor emissions are migrating offsite, understand how future infrastructure upgrades may change the odor conditions, and identify the required odor removal performance to meet the odor control objectives.

Vapor phase odor control is an effective means of treating odors from a variety of sources in a centralized system, even in large collection systems. Using the latest advances in biological odor control, high hydrogen sulfide and odor loading sources can be effectively treated in a sustainable manner with minimal operating costs and little or no chemicals. V&A uses sewer ventilation modeling to determine the capacity for airflow within collection systems, and fan testing to determine the viability of vapor phase treatment systems. Combining hydrogen sulfide and differential pressure monitoring, fan testing involves extracting known quantities of air to simulate the effects of a permanent odor control facility. V&A has used these methods to effectively size and locate vapor phase odor control facilities within wastewater collection systems from 100 cfm to over 40,000 cfm in capacity.

It is important to remember that there is not always a clear path to effectively addressing every odor complaint in a wastewater system. It often requires an iterative approach of identifying the most significant contributors, implementing the appropriate solutions, and evaluating how effective these solutions are at meeting the odor control goals. A comprehensive odor control strategy that includes investigation, evaluation, and implementation will ensure that you are headed in the right direction and enable you to set realistic expectations for your stakeholders within the available funding mechanisms.